The invention of PET flakes processing by Hurmak

The invention of PET polymer in XX century has revolutionized beverage and packaging industries. Thanks to such features as transparency, high impact resistance, non-toxicity and lack of influence on taste and smell of the packaged product, PET has shortly became basic material for production of bottles for water and soft drinks, gradually displacing packaging made of different materials.

However currently the plastic industry in Europe faces a number of challenges related to EU legislation concerning plastic products, moving away from the linear economy model in favor of the circular economy, and thus the growing importance of recycling is inevitable.

The largest European companies in the plastics industry are developing new technologies and materials, they declare the increasing use of recycled materials in their products. As it turns out, this trend, which is otherwise right, is not just about the European Union. More and more important players from outside Europe are successfully joining the process of implementing circular economy in the plastics industry.

These certainly includes us, Hürmak Plastics Machinery, as the leading Turkish manufacturer of injection molding machines. We successfully operate on the European market, with particular emphasis on Central Europe, having branches in Poland, Romania in Hungary, and since 2018 also in Russia.

Interest in the mechanical method of processing plastic waste is growing, because it is one of the simpler ways of reusing it, and EU regulations oblige member states to increase the recovery of raw materials from waste, including municipal waste. PET, on the other hand, is one of the key raw materials whose derivatives are successfully used in various industries as a result of recycling.

This is particularly important on the dynamically developing market in Poland, which is why the Polish branch of Hurmak together with other local entrepreneurs and the state research academy is implementing a project whose goal is to develop an innovative solution enabling the production of bottle preforms directly from PET flakes.

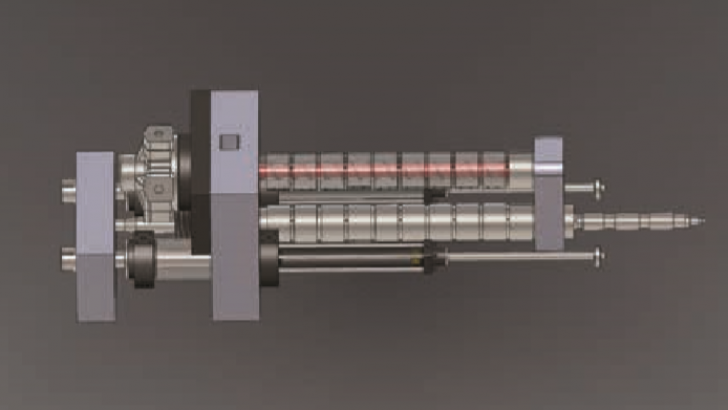

The essence of the solution is an innovative injection unit that allows homogenization of the original granulate (or re-granulate) with comminuted flakes of recycled plastic (canceling the effect of too low backfill weight and density).

The uniqueness of this solution lies in the lack of the need to prepare an initial re-granulate, which will significantly reduce the energy consumption, labor input (no need to run a separate line for granulating the mixture) and thus, reduce costs and finally the price.

The recycling process of used packaging for the raw material for secondary processing consists of collecting the packaging, grinding it into flakes, and then extruding it into the form of granules. This, however, requires the launch of an additional extrusion line.

As says Jakub Mączka – CEO of Hurmak Polska and a coordinator of this project, the efficiency and quality of plasticizing in the processing process depend significantly on the conditions of this process and the design solution of the plasticizing system. The plasticizing process of a polymer material involves the transition of the input material as a result of heating and movement from a solid state to a plastic state. The starting material must have a specific temperature, pressure and degree of mixing of the composition.

The quality and form of the input material are also important. Enabling through the use of an innovative plasticizing system, feeding input materials in various forms (granules and flakes), will allow a significant reduction in the production costs of products made of these materials, in this case PET preforms.

The implementation of the research project will ultimately allow for a significant improvement of the technological process of producing PET preforms by eliminating flake re-granulation in a separate extrusion process. This will save 50% energy consumption in the preform production process.

On the other hand, better homogenization of the material will allow to increase the share of recycled material, up to 100%, and the expected reduction in preform production costs is estimated at even 50%, which will significantly increase the price competitiveness of the product while maintaining its quality.

It is extremely important, which should also be remembered, that with each recycling cycle the material properties deteriorate. The innovation developed by the R&D department of Hürmak together with Polish scientists – by removing the re-granulation stage – will also extend the life of the secondary raw material.

Source: PLASFEDMAG

Editor Note:

If you want detailed information or for contact to corporate write to us with news headline; contact@pnturkey.com or WhatsApp; api.whatsapp.com/send?phone=905544041381

Follow this link to join pnTurkey WhatsApp group: https://chat.whatsapp.com/